The L‑ROC Room Controller provides the basis for a revolutionary room automation system based on IP, which seamlessly integrates with native BACnet/IP networks and LonMark Systems at the controller level. Together with the L‑STUDIO software, flexible room solutions can be created and adapted to changing requirements during the project with little effort. Integral parts of the L‑ROC System are a web-based room operation via an LWEB‑802/803 dashboard and the automatic generation of graphics for the L‑VIS Touch Panel for local operation.

Our room controllers provide all common interfaces and a large number of physical I/Os for room automation projects. KNX devices are integrated via the built-in KNX TP1 or the KNXnet/IP interface. DALI lamps and DALI sensors are connected to the DALI interface with an integrated DALI power supply. Up to 16 SMI sunblind motors connect to the SMI interface. Belimo valves connect to the MP-Bus interface. BACnet MS/TP devices connect to the RS‑485 interface, which can also be configured as a Modbus RTU/ASCII interface to connect Modbus devices like energy meters or ekey finger scanner for access control. L-STAT room operator panels connect to the dedicated L-STAT interface. The EXT interface can connect 16 more SMI sunblind motors through the LSMI-800 interface or M‑Bus meters through the L-MBUS20 interface. EnOcean devices connect to the EnOcean interface through an external antenna. Dual Ethernet ports allow daisy chaining of L‑ROC controllers in a ring topology and provide BACnet/IP, LON/IP, Modbus/IP, KNXnet/IP and OPC communication. Optionally the L‑ROC can communicate via wireless LAN through the LWLAN‑800 wireless adapter connected to the USB port. 24 relay outputs, 8 TRIAC outputs, 8 analog outputs, 10 universal inputs and 2 digital inputs connect various physical inputs and outputs. Our room automation library provides pre-built function modules for all lighting, heating, cooling, ventilation, sunblinds and access control via finger scanners. Built-in SSL encryption ensures secure operation of the room automation system.

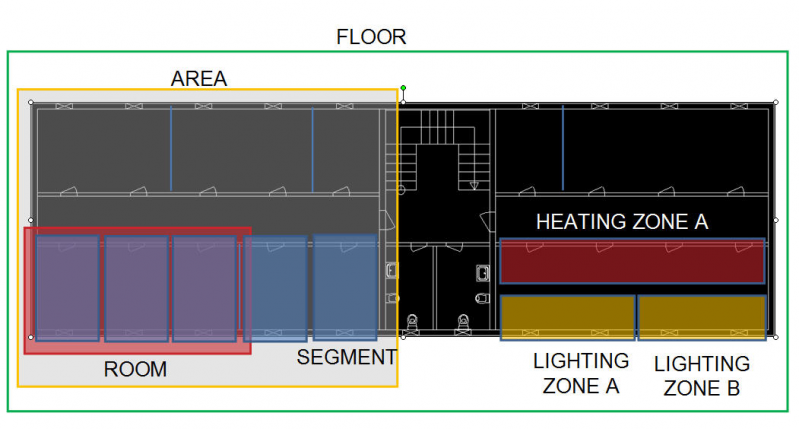

Flexible Room Concept for Room Automation

A room segment is the base unit of configuration in the L-ROC System. The L-ROC Room Controller provides a set of functions for every window axis including:

- Lighting control with constant light controller

- Sun blind control with sun tracking and year shade progression

- Temperature control for heating, cooling, and ventilation

- Occupancy detection

- Window monitoring and window contact

Depending on the model an L‑ROC Room Controller can control between 8 and 16 room segments. Based on the various room segment types, larger buildings can be modeled in a hierarchical manner. Areas are built with an area manager by combining multiple room controllers. A floor manager manages multiple areas in one floor. Depending on the architecture, the building can be split up into areas and floors as needed.

Area/Floor Managers are responsible for handling functions needed for corridor, staircase, and bathroom lighting, or even ventilation. Floor managers facilitate the data communication between the floors and handle floor relevant functions e.g. processing meter data.

Rooms can be created in any size by moving, installing, or removing partition walls. The resulting logical connections between the L‑ROC Room Controllers will be built automatically. All graphical user interfaces and network connections are automatically generated and adapted respectively.

AST™ for Every Room Segment

L‑ROC provides a set of functions for Alarming, Scheduling, and Trending (AST™) for every room segment. Each room segment can be operated entirely independently. The AST™ functions are fully available to higher-level systems through BACnet/IP and web services (L‑WEB System). Distributed schedulers can be efficiently managed and changed with LWEB‑900.

Room Communication through redundant or seperated IP Network

L‑ROC Room Controllers are interconnected via a 100Base-T Ethernet network. Each L‑ROC device is equipped with two Ethernet ports. It can either be configured to use the internal switch to interconnect the two ports or every port is configured to work in a separate IP network.

When the Ethernet ports are configured for two separate IP networks, one port can be connected for instance to a WAN (Wide Area Network) with enabled network security (HTTPS) while the second port can be configured to be connected to an insecure network (LAN) where the standard building automation protocols like BACnet/ IP, LON/ IP, or Modbus TCP are present. These devices also feature firewall functionality of course to isolate particular protocols or services between the ports. The built-in VPN function provides for simple VPN setup and secure access to remote sites. The LTE-800 interface enables wireless access to remote sites through a mobile carrier.

Using the internal switch, a daisy chained line topology of up to 20 devices can be built, which reduces costs for network installation. The IP switch also allows the setup of a redundant Ethernet installation (ring topology), which increases reliability. The redundant Ethernet topology is enabled by the Rapid Spanning Tree Protocol (RSTP), which is supported by most managed switches.

Integrated L-WEB Room Operation

L‑ROC controllers provide graphical user interfaces for room operation directly via an IP connection to the user, without the need for an additional web server. Graphic projects are distributed among the L‑ROC Room Controllers and can be accessed by LWEB‑802/803 from any PC workstation, smart phone, or tablet PC running Android or iOS.

Integration of the L-STAT Room Operator Panel

Depending on the model, 8 to 16 L-STAT Room Operator Panels can be integrated via the L-STAT interface per L‑ROC Room Controller. In addition to the attractive, modern design and intuitive operation, L-STAT provides a range of features to individually increase the room comfort.

Internal sensors measure temperature, humidity, dew point, occupancy, and the CO2 content of the air. There is also the possibility to control room functions via an IR remote control. Standard pushbuttons and external temperature sensors can be integrated through additional inputs.

Connection to Higher-Level Systems

Higher-level systems can seamlessly integrate L‑ROC Room Controllers via BACnet/IP, LonMark IP‑852, or web services (OPC).

All these protocols are simultaneously available. It is possible to integrate the L‑ROC Room Controller in a BACnet Operator Workstation and at the same time L‑ROC will communicate with other CEA‑709 devices on the IP‑852 channel. Moreover, a higher-level SCADA or ERP System (Facility Management) gets information directly from the L‑ROC Room Controller by using web services based on OPC XML‑DA or OPC UA.

Full LWEB-900 Support

The L‑WEB System uses web services to communicate with the L‑ROC System. All device and operating parameters of every single L‑ROC Room Controller are automatically synchronized with the LWEB‑900 SQL database. Controllers can be replaced from the database with a backup without user interaction.

I/O Integration via Plug and Play

The L‑ROC Room Controllers can automatically integrate additional physical I/Os by using L‑IOB I/O Modules. Up to 2 L‑IOB I/O Modules can be connected through LIOB‑IP. All I/Os can be used by the L‑ROC application and are also available via the web interface of L‑ROC. All configurations of the L‑IOB Modules are stored on the L‑ROC and loaded on demand into the L‑IOB I/O Modules. Exchanging I/O modules is done without any configuration effort requiring only a few quick configuration steps.

Year Shade Progression

Especially in dense city areas, buildings can cast shadows on each other. In case a façade element is shaded by another building, sunblinds can be deactivated for better daylight harvesting. The high-performance L-ROC controllers allow to calculate a 3D model in dxf-Format of the building and its close-by neighbors. The model can be constructed using common 3D CAD software or can be derived from a Building Information Model. In case the scenery changes due to new constructions, only the new buildings have to be inserted in the model. The calculation can be done for each window individually or per shadowing zone.

IoT Integration

The IoT function (Node.js) allows connecting the system to almost any cloud service, either for uploading historical data to analytics services, delivering alarm messages to alarm processing services or operating parts of the control system over a cloud service (e.g., scheduling based on Web calendars or booking systems). Processing Internet information such as weather data in forecast-based control is also possible. Finally, the JavaScript kernel also allows implementing serial protocols to non-standard equipment.

L-STUDIO

L‑STUDIO is the world’s first IEC 61499 based room automation system. Any room function can be realized with L‑STUDIO in a distributed system of L‑ROC devices. We call this new approach in automation “Cloud Control”. In a cloud of L‑ROC devices, all automation functions are mapped automatically o physical hardware. The object-oriented design method allows the efficient reuse of previously implemented functions. In the graphical development environment of L‑STUDIO, areas are created from room segment with just a few mouse clicks. The areas are interconnected to floors and multiple floors form a building. The entire building application is automatically distributed to the L‑ROC Controllers installed in the building.

L‑STUDIO is the world’s first IEC 61499 based room automation system. Any room function can be realized with L‑STUDIO in a distributed system of L‑ROC devices. We call this new approach in automation “Cloud Control”. In a cloud of L‑ROC devices, all automation functions are mapped automatically o physical hardware. The object-oriented design method allows the efficient reuse of previously implemented functions. In the graphical development environment of L‑STUDIO, areas are created from room segment with just a few mouse clicks. The areas are interconnected to floors and multiple floors form a building. The entire building application is automatically distributed to the L‑ROC Controllers installed in the building.

New functions can be added to the room segment objects after initial configuration. These new functions can be applied individually or to all room segment objects very easily. Comprehensive debugging and watch functions allow for complete building troubleshooting. An extensive library of functions is provided for heating, ventilation, cooling, lighting, sun blind control, and security. With the integrated L‑VIS/L‑WEB Configurator, graphical pages for L‑VIS Touch Panels and L‑WEB applications can be customized.

Features

- Flexible built-in management for room segments

- Room controller for up to 8 or 16 room segments

- Networking via redundant IP network

- Programmable with L‑STUDIO (IEC 61499)

- Extension with physical inputs and outputs using L‑IOB I/O Modules (LIOB‑45x or LIOB‑55x)

- 128×64 graphic display with backlight for device configuration and maintenance

- Local display of device and data point information

- Manual operation using the jog dial or VNC Client

- Integrated AST™ functions (Alarming, Scheduling, and Trending) for each room segment

- Node.js support for easy IoT integration (e.g. Google calendar, Alexa & friends, multimedia equipment,…)

- Event-driven e-mail notification

- Math objects to execute mathematical operations on data points

- Stores customized graphical pages

- Visualization of customized graphical pages through LWEB‑900 (Building Management), LWEB‑803 (Monitoring and Control), or LWEB‑802 (Web Browser)

- Support of the L‑STAT Network Thermostat

- Built-in OPC XML‑DA and OPC UA server

- Access to network statistics via SNMP

- Compliant with ANSI/ASHRAE 135‑2012 and ISO 16484‑5:2012 standard

- Supports BACnet MS/TP, BACnet/IP or BACnet/SC

- BACnet Client Function (Write Property, Read Property, COV Subscription)

- BACnet Client Configuration with configuration tool (scan and EDE import)

- B-BC (BACnet Building Controller) functionality, BTL-certified

- Integrated BACnet/ IP to BACnet/SC and BACnet MS/TP Router including BBMD as well as Slave-Proxy functionality

- Compliant with CEA‑709, CEA‑852, and ISO/IEC 14908 Standard (LonMark System)

- CEA‑709 integration via LonMark IP‑852 (Ethernet/IP) channel

- Support of dynamically created or static NVs

- Support of user-defined NVs (UNVTs) and Configuration Properties (SCPTs, UCPTs)

- Connection to KNXnet/IP and KNX TP1

- M‑Bus Master according to EN 13757‑3, connection via optional M‑Bus Converter (L‑MBUS20 or L‑MBUS80)

- Gateway functions including Smart Auto-Connect™

- Modbus TCP and Modbus RTU/ASCII (Master or Slave)

- Integrated web server for device configuration and monitoring data points

- Integration of actuators via MP-Bus

- DALI Integration of up to 64 DALI lamps (depending on the model)

- Integrated DALI power supply, 16 V DC, 230 mA guaranteed supply current, 250 mA max. supply current

- Test and assignment of DALI devices via the Web interface

- Replacement of DALI devices without additional software tools via the graphic display and jog dial

- Supports up to 16 DALI sensors

- Supports up to 64 DALI pushbuttons

- Supports the control of standard loads in the power grid via LDALI‑RM3 Relay Modules

- Supports DALI-2 devices (drivers and input devices)

- DALI-2 certified, compliant with IEC 62386-101 and IEC 62386-103 (only LROC-400, LROC-401)

- Supports DALI color control (DT8 tunable white & full color control)

- Integrated Constant Light Controller

- Supports lamp burn-in mode

- Supports periodic testing of DALI emergency lights

- Integrated DALI Protocol Analyzer

- Connection to EnOcean wireless devices (built-in EnOcean interface with external antenna for Europe, 868 MHz) or via LENO‑80x

- Supports WLAN through LWLAN‑800 Interface

- Supports SMI (Standard Motor Interface):

LROC-400, LROC-401: built-in (expandable via LSMI-80x)

LROC-402: needs LSMI-804 - Supports LTE through LTE-800 Interface

- Stores user-defined project documentation

- Configurable Bluetooth beacons and services: indoor navigation, asset tracking (requires LIC-ASSET license) and access to LWEB-900 room control solution (only LROC-400/LROC-401)

L-ROC Room Automation – Video

LROC-40x Room Controller Products

LROC-400

L-ROC Room Controller for room segment, aisle, floor, building, or campus management

LROC-401

L-ROC Room Controller for room segment, aisle, floor, building, or campus management

LROC-402

L-ROC Room Controller for room segment, aisle, floor, building, or campus management

LROC-SEG8

License to add 8 segments to L-ROC controller

L-STUDIO

Device configuration and programming suite

LIC-ASSET

LIC-ASSET, Add-on Software License to activate asset tracking (for LDALI-ME20x-U, LDALI-3E10x-U, LDALI-PLCx, LROC-400, LROC-401, LIOB-AIR20, LIOB-591)

LBOX-ROC1

System Distribution Box for LROC-40x Room Controller, 519 x 280 x 71 (L x W x H in mm)

LBOX-ROC2

System Distribution Box for LROC‑40x Room Controller, 60 W 24 V DC power supply

LOY-DALI-SBM1

LOY-DALI-SBM1 Sunblind Module

LENO-800

EnOcean Interface 868 MHz Europe

LENO-801

EnOcean Interface 902 MHz USA/Canada

LENO-802

EnOcean Interface 928 MHz Japan

LSTAT-810-G3-L0

Remote EnOcean Antenna, Europe, White

LSTAT-820-G3-L0

Remote EnOcean Antenna, USA/CA, White

LSTAT-830-G3-L0

Remote EnOcean Antenna, Japan, White

LSTAT-80x-CUSTOM

One-time customization cost for L-STAT custom design, including 2 working samples

LWLAN-800

Wireless LAN Interface IEEE 802.11bgn

LSMI-804

Standard Motor Interface for 64 motors, 4 SMI channels via USB

LSMI-800

Standard Motor Interface for 16 motors via EXT port

LRS232-802

L-TRIAC16

TRIAC Interface, 16 x Digital Output 0.5 A TRIAC, 16 x Digital Input (0/10 V)

LOYCNV-VA8

Voltage / Current Converter, 8 channels, 0-10 V input to 4-20 mA output converter

LOYREL-816

Relay Interface, 8 x Digital Output 16 A Relays, 8 x Digital Input 0/10 V

L-TEMP2

External temperature sensor (NTC10K) for use with L-IOB Universal Inputs

LDALI-MS2-BT

DALI-2 multi-sensor (presence detection, illuminance sensor, IR receiver, temperature sensor, humidity sensor, 3 digital inputs, Bluetooth), up to 12 m mounting height

LDALI-MS4-BT

DALI-2 multi-sensor (presence detection, illuminance sensor, IR receiver, temperature sensor, humidity sensor, 3 digital inputs, Bluetooth, flat lens), up to 5 m mounting height

LDALI-BM2

Quadruple DALI pushbutton coupler

LDALI-RM5

DALI Relay Module 10 A, Analog Interface 1 – 10 V

LDALI-RM6

DALI Relay Module 10 A, Analog Interface 1 – 10 V, “spud-mount”

LDALI-RM8

DALI Relay Modul, 8 channel

LDALI-PD1

DALI Phase-Cut Dimmer Module

LDALI-PWM4

PWM module, DALI, 4 x 3 A LED outputs, 24 V DC ext.

LDALI-PWM4-TC

PWM module tunable white, DALI, 4 x 3 A LED outputs, 24 V DC ext.

LDALI-PWM4-RGBW

PWM module RGBW, DALI, 4 x 3 A LED outputs, 24 V DC ext.

LIOB-450

LIOB-IP852 I/O Module: 8 UI, 2 DI, 2 AO, 8 DO (4 x Relay 6 A, 4 x Triac 0.5 A)

LIOB-451

LIOB-IP852 I/O Module: 8 UI, 12 DI

LIOB-452

LIOB-IP852 I/O Module: 6 UI, 6 AO, 8 DO (8 x Relay 6 A)

LIOB-453

LIOB-IP852 I/O Module: 6 UI, 6 AO, 5 DO (4 x Relay 16 A, 1 x Relay 6 A)

LIOB-454

LIOB-IP852 I/O Module: 7 UI, 4 AO, 7 DO (5 x Relay 6 A, 2 x Triac 0.5 A), 1 Pressure Sensor

LIOB-550

LIOB-BIP I/O Module: 8 UI, 2 DI, 2 AO, 8 DO (4 x Relay 6 A, 4 x Triac 0.5 A)

LIOB-551

LIOB-BIP I/O Module: 8 UI, 12 DI

LIOB-552

LIOB-BIP I/O Module: 6 UI, 6 AO, 8 DO (8 x Relay 6 A)

LIOB-553

LIOB-BIP I/O Module: 6 UI, 6 AO, 5 DO (4 x Relay 16 A, 1 x Relay 6 A)

LIOB-554

LIOB-BIP I/O Module: 7 UI, 4 AO, 7 DO (5 x Relay 6 A, 2 x Triac 0.5 A), 1 Pressure Sensor

LIOB-560

LIOB-BIP I/O Modul: 20 Universal I/O (IO)

LIOB-562

LIOB-BIP I/O Module: 40 Universal I/O (12 optionally with 4-20 mA Current Output)